About Hot Spots®

Don’t let your conveyance system get beyond control

Many underground coal mine fires have been attributed to “hot” roller fires. Be proactive and resilient towards conveyor compliance and safety, keep your conveyors safe, efficient and reliable.

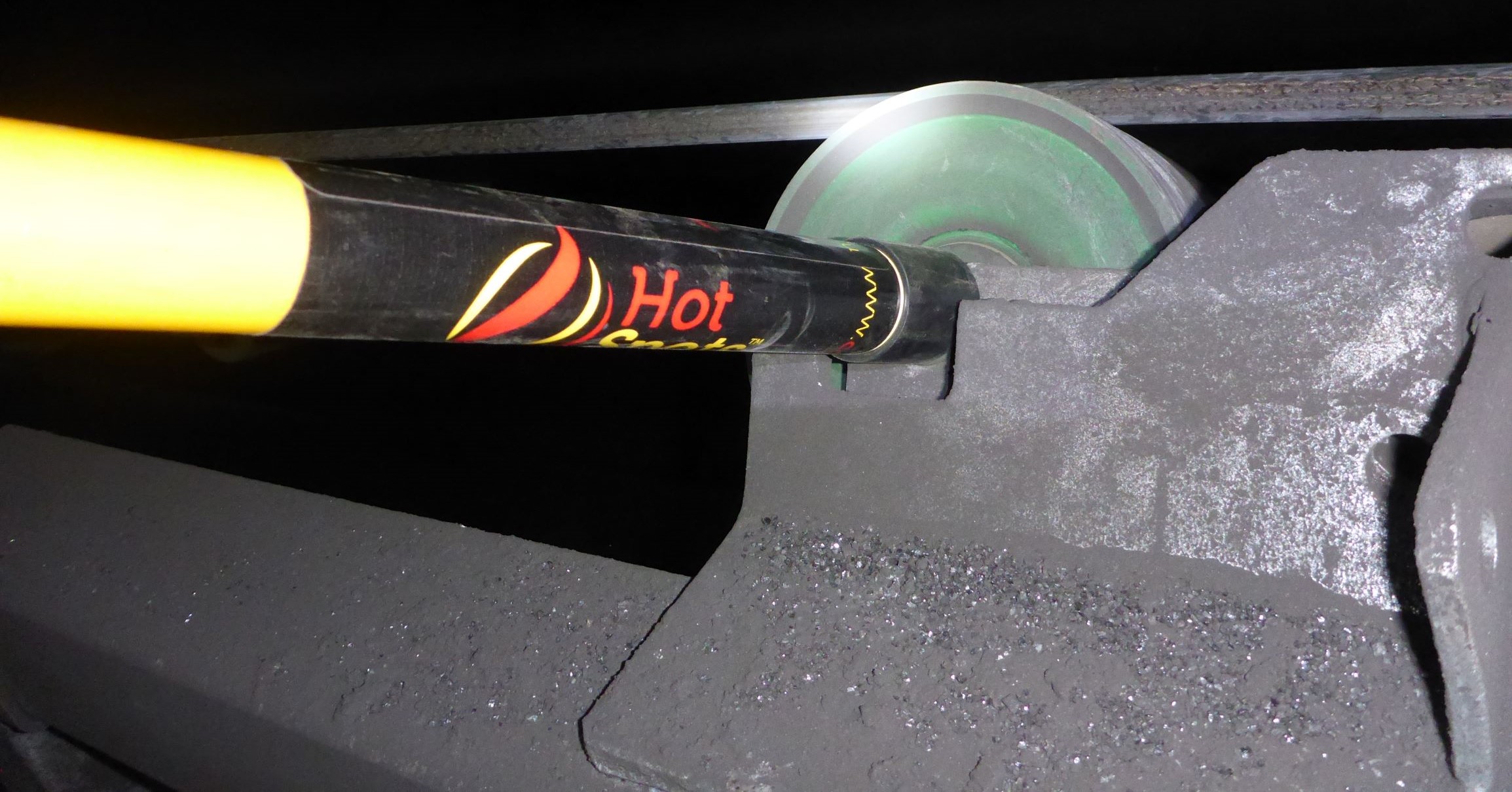

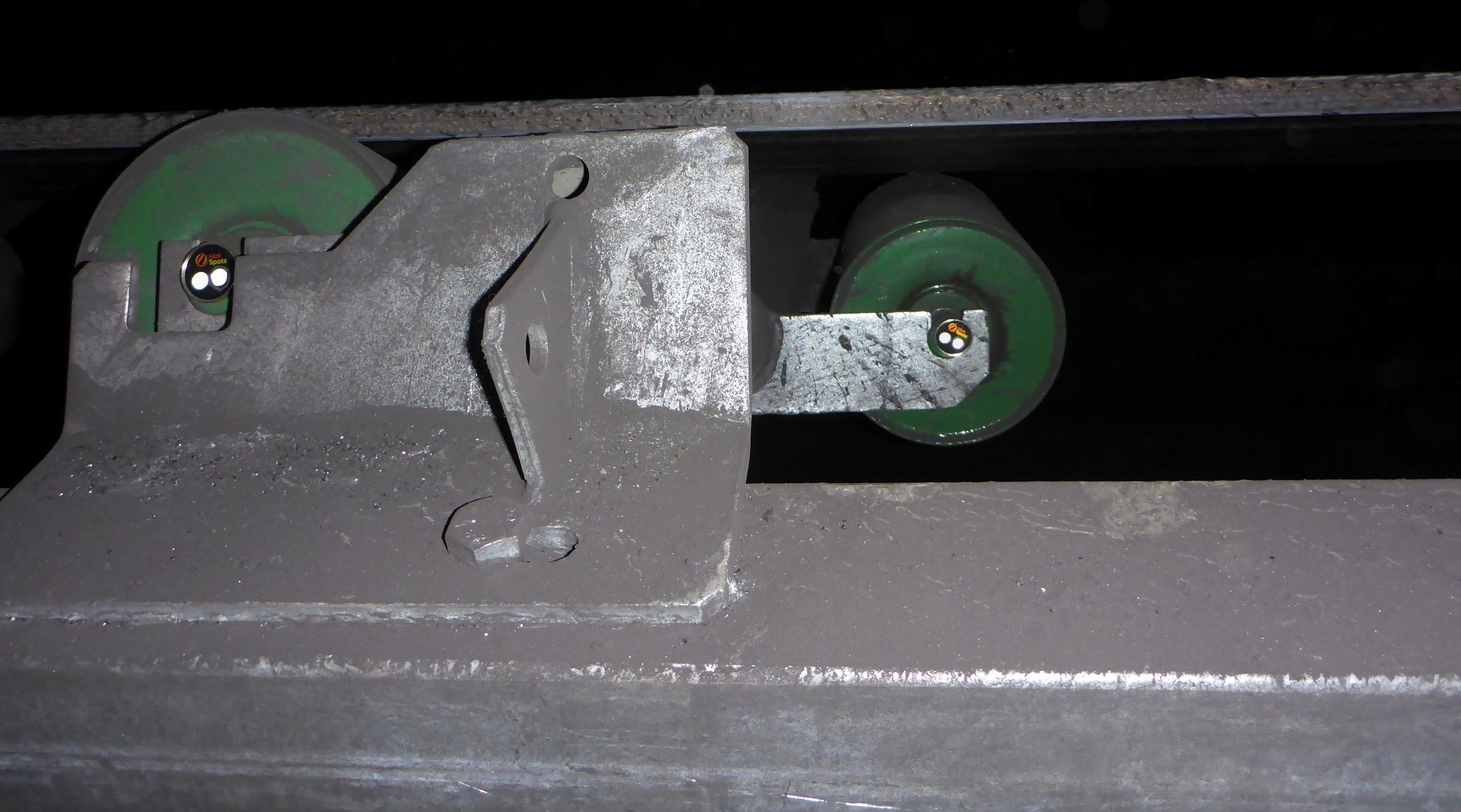

The Hot Spots® predict to prevent approach assists in the early detection of deteriorating idler bearings, improving the reliability and availability of the system, through consistent informed inspections supporting an effective maintenance strategy.

Applications

Designed for conveyors, Hot Spots® has a wide range of uses across both fixed and mobile equipment:

- Idlers

- Rollers

- Pulley’s

- Anti-runbacks

- Gearboxes

- Electric Motors

- Wheel Hubs

- Electric trailing cables, plugs and transformers

- Hydraulics

- Friction points

Hot Spots® Range

Hot Spots® Dual Stage Detectors >60°C and >100°C

Hot Spots® Single Stage Detector >90°C

Hot Spots® 1000 Kit

2 x Hot Spots® Stainless Steel dispenser closing caps

Hot Spots® Customised Kits on Request

Hot Spots® UPVC Dispenser

Hot Spots® Stainless Steel / UPVC personal dispenser complete with 12 Hot Spots®.

Hot Spots® Stainless Steel Dispenser

Hot Spots® Stainless Steel personal dispenser complete with 12 Hot Spots®.

Hot Spots® Stainless Steel Dispenser Closing Cap

Advantages

Simple – No electrics, no equipment retro fitting and no scheduled maintenance required.

Affordable – Inexpensive, disposable and can be applied during routine maintenance activities.

Functional– Informed Statutory Inspections. Informed maintenance decisions.

Effective – Visible, reflective and durable. Quick and easy early detection of a failing idler bearing.